Self-Healing Polymers

The Moore group is actively pushing the capability of self-healing systems towards larger scales and commercialization. Our current work uses microvascular self-healing material systems which have attracted attention for their ability to achieve multiple healing cycles in response to mechanical damage.

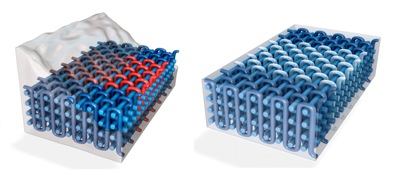

The development of sacrificial fibers has brought self-healing into common manufacturing materials such as fiber-reinforced composites. With the “VaSC” method (Vaporization of Sacrificial Components), we have created microvascular composites with channel lengths up to one meter. Pluripotent composite materials are manufactured by circulating fluids with unique physical properties where the solid phase provides strength and form and the liquid phase provides interchangeable functionality.

Using the generality and compatibility of vascularized composites, our group is exploring multi-stage healing fluids. The liquid healing agents used in microvascular-based healing systems wick into internal cracks and surface scratches to effectively glue the material together. When a material is catastrophically damaged and loses mass (e.g. ballistic impact), these traditional healing systems fail to replace the lost material and drip out of the damage region. We created a two-stage polymeric approach that incorporates monomer gelation with polymerization to regenerate material approximately 100 times larger than previously possible. Two healing fluids were created that are inert until mixed. Once the solutions mix, they quickly react to form a gel scaffold which holds the material in the damage. Additional fluids are deposited and gel until the entire damage is filled. A subsequent polymerization stage recovers the mechanical properties of the original material. This two-stage approach can heal punctures up to 9 mm in size and has applications ranging from aerospace to civil infrastructure.

Our self-healing research is done in collaboration with the Autonomous Materials Systems division of the Beckman Institute at the University of Illinois.

Latest healing work: Regenerating Plastic Grows Back After Damage

Healing of impact damage in a thin plastic sheet. Microvascular channels are filled with two fluorescently dyed solutions. The solutions mix in the damage site and form a scaffold for additional fluids to be deposited. After filling the damage, the fluids polymerize to fully regenerate the material.

Schematic diagrams of VaSC fabrication procedure. Left: Sacrificial fibers (red) interwoven into 3-D glass fiber tows (blue) and epoxy resin (light gray) infuses this perform; Right: Thermal depolymerization and monomer vaporization results in 3D microvascular network integrated into a structural composite.